Useful Information

20 november 2021 at 16:37

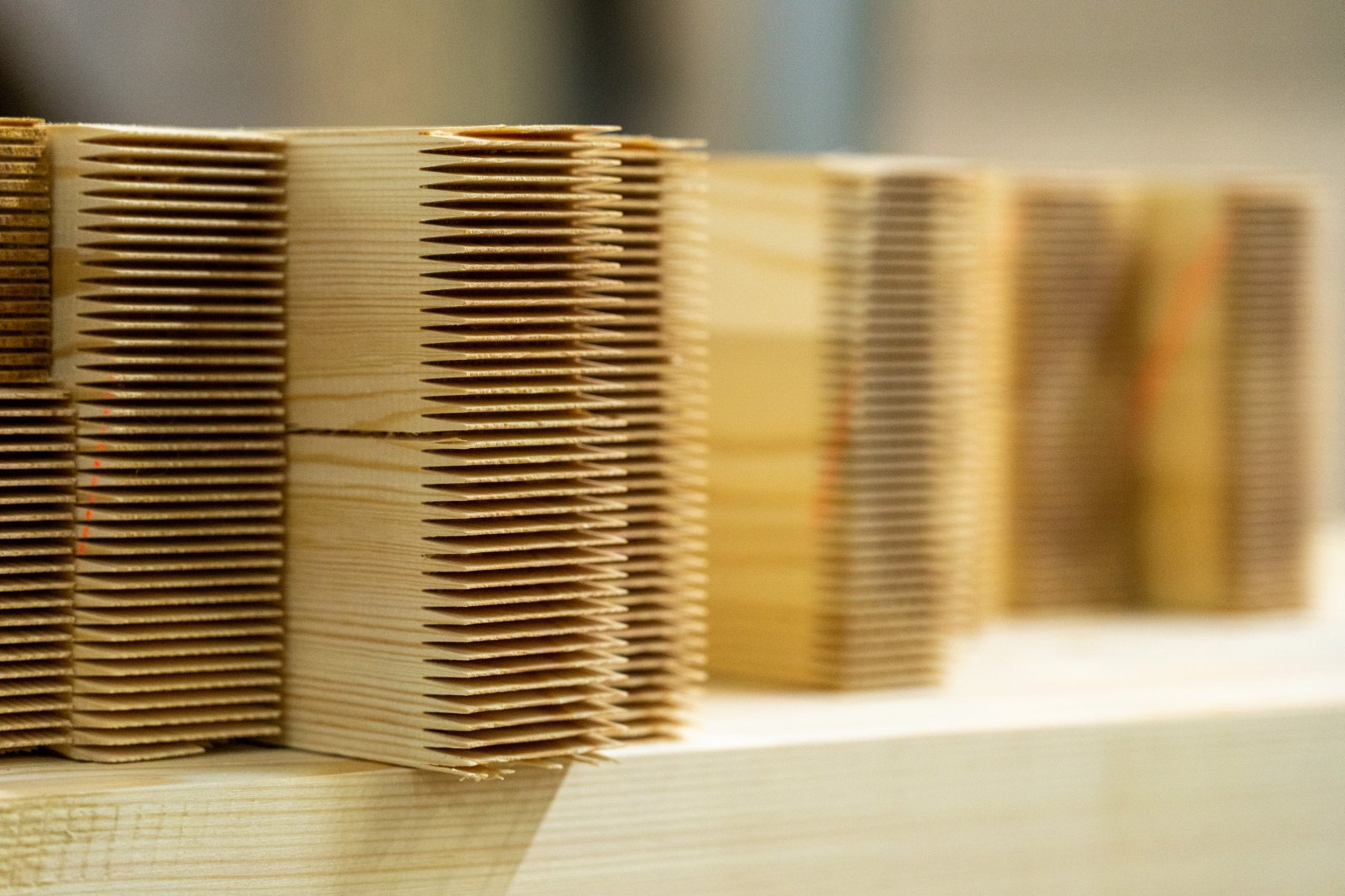

Energy-efficient, environmentally friendly and safe construction material, glued laminated timber is the choice of practical homeowners.

The tranquility and harmony of life outside the city. A beautiful cozy house, a quiet morning in the garden, an evening by the fireplace… A house – what should it be like for a comfortable life? Durable, warm, eco-friendly, reliable. Do you agree? Then you need a house made of glued laminated beams of Russian production. Why exactly this – let's analyze it in order.

What kind of material is this?

Glued laminated timber is a material made of wood produced by gluing together defect-free boards (lamellas). The abbreviated international designation is Glulam (glued laminated timber). The widespread use of such structures began in Finland in the 1960s and 1970s of the last century. This type of lumber has become a new solution in the construction of houses due to its valuable properties. Since then, glued beams have become more and more in demand in the construction market every year.

Why glued, and not solid

If we compare glued laminated timber with its closest competitor – profiled timber, there are a number of obvious advantages.

- Endurance. According to experts, glued laminated wood structures have 50-70% greater strength compared to solid wood. Houses made of glued laminated beams are suitable for places with problematic soils, as well as for areas with high seismicity. By the way, this material is used for construction in Japan, including the restoration of areas affected by earthquakes.

- Durability. This material is resistant to moisture and temperature changes. Modern glued laminated beams are resistant to rotting and serve for about 100 years.

- Environmental friendliness. Volatile substances useful for human health are released from the open surface of the beam, which supports a healthy microclimate in a room. In addition, the construction of houses made of glued laminated beams does not require cutting down trees adjacent to the building spot. This reduces the load on the landscape, ecosystem and eliminates the contamination of the territory with construction waste.

- Fire resistance. If a spark gets on the glued laminated beam, the fire will not start immediately or will not start at all. And structures made of glued laminated wood treated with flame-retardant and antiseptic compounds are not subject to bio-contamination in conditions of high humidity.

- Stability of forms. Glued laminated wood, unlike solid wood, retains its shape and size over time, practically without shrinkage. Houses made of such material can be exploited immediately after construction, this is perhaps one of the most important advantages over profiled timber, as well as over chopped and rounded logs.

- The length of the lamellae from which the glued laminated beam is assembled reaches 15 meters, and the maximum length of the profiled beam is only 6 meters, which gives designers more freedom when choosing sizes.

- Heat resistance. According to experts, the coefficient of resistance to thermal conductivity of the wall is 196 mm – 2.08, which is equivalent to 1000 mm of brickwork. This means that the heating costs of the house will be significantly less and it will not need to be additionally insulated.

- Aesthetics. The external lamellae of the beam actually have no natural flaws, since when sorting the board, those that actually do not contain flaws are selected. With the right choice of impregnations and decorative finishing coatings, they will not require cosmetic repairs for many years.

Facts about the manufacturer

- Babaevsky woodworking plant uses the highest quality coniferous wood from the forests of the Vologda region.

- The plant has been specializing in the production of houses made of structural glued laminated beams since 2000.

- It has its own full-cycle production, modern high-precision equipment.

- It controls the quality of materials at every stage of production.

- It produces a wide range of sizes that meet high quality standards.

- The plant cooperates with many exporters of construction raw materials and construction organizations. It supplies timber, according to the terms of the international rules of Incoterms, to any country.